Introduction

The agricultural sector is witnessing a digital transformation that mirrors the evolution of other industrial domains. Modern tractors, harvesters, and irrigation systems now rely on a sophisticated blend of sensors, data analytics, and precision control to deliver higher yields and lower operating costs. At the heart of this shift lies the humble DC gear motor. Though often overlooked, the careful selection of these motors dictates the performance, reliability, and efficiency of intelligent agricultural equipment.

Why DC Gear Motors Matter

DC gear motors offer several distinct advantages for agricultural machinery:

These qualities translate directly into the core capabilities of intelligent manufacturing: rapid prototyping, adaptable control loops, and energy‑efficient operation.

Key Factors in Motor Selection

Choosing the right DC gear motor involves balancing several parameters, each influencing the final product’s intelligence and longevity.

| Parameter | Why It Matters | Typical Range for Agricultural Use | |-----------|----------------|-----------------------------------| | Torque & Speed | Drives loads while maintaining accuracy. | 10 – 100 Nm at 100–2000 rpm | | Power Rating | Determines total energy consumption and feasibility. | 0.5 – 5 kW | | Gear Ratio | Sets the effective speed‑torque output. | 20 : 1 to 100 : 1 | | Environmental Sealing | Protects against dust and water. | IP67 or higher | | Control Interface | Integrates with PLC or microcontroller dashboards. | PWM, analog‑in, or CAN‑bus |

These criteria become even more critical when integrating with higher‑level systems such as machine vision, GPS guidance, and cloud analytics. For example, a motor that delivers insufficient torque may fail to keep a robotic arm aligned with a vision‑guided seed planter, leading to misplanting and crop loss.

Integration with Intelligent Manufacturing Systems

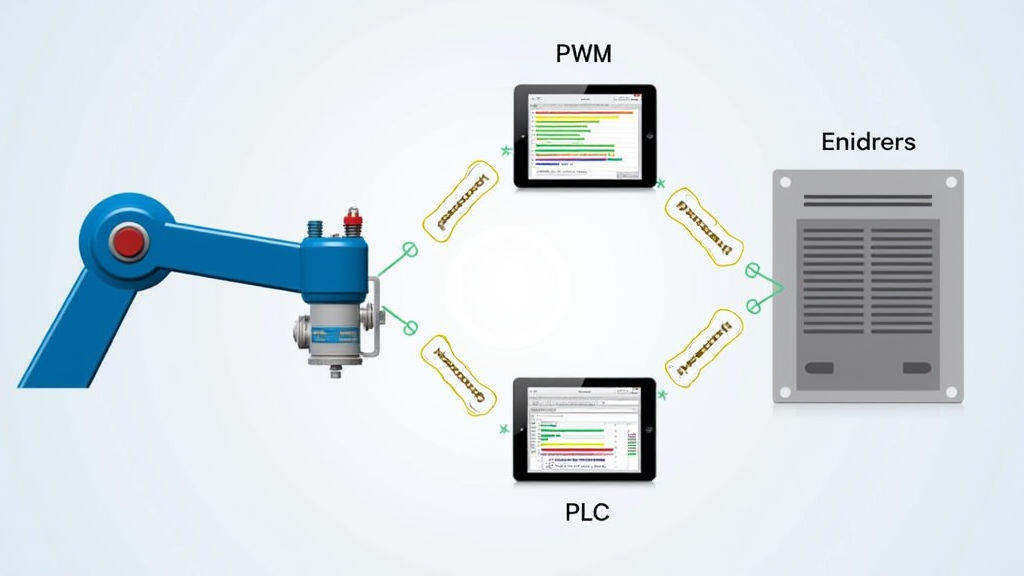

Modern agricultural machines often operate within a connected ecosystem. DC gear motors serve as the mechanical output nodes that translate electronic decisions into physical actions.

By selecting motors that are compatible with common industrial communication standards (e.g., Modbus, EtherCAT) manufacturers can embed intelligence without re‑engineering entire drives.

Case Study: Autonomous Soil‑Moisture Sampling

A mid‑size agri‑tech startup introduced an autonomous soil‑moisture sampler that travels across a field, collecting cores at predefined intervals. The system relies on a 150 Nm DC gear motor to drive a down‑loading arm. Key selection points addressed in the design:

The resulting device achieved over 98 % sampling accuracy and reduced manual field labour by 70 %, showcasing how the right motor underpins successful intelligent machinery.

Future Outlook

The next generation of agricultural equipment will likely incorporate:

Moreover, advances in additive manufacturing promise lighter, more efficient motor housings that further reduce vehicle weight, enhancing energy efficiency and payload capacity.

Conclusion

Selecting the appropriate DC gear motor is not a mere part of the design process—it is the decisive factor that turns isolated mechanical components into fully intelligent agricultural systems. From delivering precise torque and speed to facilitating real‑time feedback and predictive maintenance, these motors are the anchors of today’s smart farms. As the industry pushes toward greater automation, sustainability, and data‑centric decision making, the role of thoughtfully chosen DC gear motors will only grow stronger, enabling agricultural machinery that is more effective, reliable, and future‑ready.

Leave A Reply

Your email address will not be published. Required fiels are marked